The Beginner’s Guide To Pressure Washer Hose Fittings, Couplers and Adapters

This guide will teach you everything you need to know about pressure washer hose fittings, couplers and adapters. All the different types, sizes, materials and naming conventions used.

What the different fittings, couplers and adapters help you do (with 4 examples).

And how to select the correct one for your setup.

Why are Pressure Washer Fittings Needed?

A pressure washer fittings connects pressure washer parts. It fits between the high pressure hose and trigger gun or between the pump and pressure hose to make them connect properly.

Your pressure washer will come with the fittings, couplers and adapters needed to make it work out-of-the-box (99% of the time).

You will only start to need fittings when you:

- Want to add attachments (surface cleaner, foam cannon, pressure gauge)

- Want to use a different high pressure hose (or extend the length of the one you have)

- Want to turn screw fittings to quick connect

- Want to better avoid hose kinks by using swivel fittings.

Fittings are inexpensive ($5 to $15), long lasting and are to make your life easier. There’s hundreds of different fittings to choose from, but only a couple of types you need to know about.

Types

Fittings, Couplers, Adapters

Fittings, couplings and adapters can be considered the same thing. Sometimes a website will refer to the entire category of connectors as fittings and then specific types of fittings as couplers or adapters or reducers. But it’s confusing and we won’t do that here.

However, we will talk about quick connect fittings and swivel fittings separate.

Quick Connect (QC) Fittings

Quick connect fittings turn screw connections to quick connect/release making the job of connecting and removing the hose fast and easy.

Female quick connect hose fittings (sometimes called sockets) have an o-ring to prevent leaks. The male side (the bottom one in the picture) are sometimes called the plug.

These days most hoses will come with QC connections out-of-the-box.

Swivel

Swivels stop the hose from kinking when in use and help to unkink it when you first walk out the hose.

It works by allowing swivel (spinning) of the hose without you having to twist the spray gun and extension wand in big circles. You can just walk it out and the gun swivel twists out the hose kinks as you walk. It’s one of those fittings you can’t pressure wash without once you try it.

Check how a swivel fitting works in this video we made:

Materials Used to Make Fittings

Consider what a fitting must do:

- It has to be strong enough to withstand 1000 – 4000 psi over (most likely) thousands of cycles use

- It needs to firmly connect the parts together and not break despite the constant tugging by the user

- It needs to be corrosion resistant since its water within, and

- It has to be cheap enough to make them a profitable product for business.

Brass, plastic and stainless steel are the most common material used in pressure washer hose fittings.

Brass is the most common. Then plastic (there’s lots of residential electric pressure washers out there). Then stainless steel (very common in professional use due to chemical resistance).

Let’s look at the pros and cons of each:

Plastic

Plastic fittings will only be used for lighter-duty electric pressure washers.

- Pros – Cheap. Light.

- Cons – Prone to cracking and damage.

Brass

Brass is by far the most common fitting material for pressure washers. It is an alloy of copper and zinc and with its low melting point is easy to cast and machine.

- Pros – Strong. Corrosion resistant. Easy to machine to different shapes. More affordable than stainless steel.

- Cons – More expensive than plastic.

Stainless Steel

Stainless steel has added chromium to prevent rust.

- Pros – Best for corrosion resistance. Chemical resistant. High strength.

- Cons – Expensive.

Rubber O-rings

O-rings are used in the female fittings to prevent leaks. The quick connect male fits into the female socket and the o-ring is the perfect size to prevent leaks.

Sizes

The main confusion when buying fittings is the size you need to get.

- Is it the inside or outside diameter you measure?

- Do you include the thread in that measurement?

- How precise do you need to be?

Even with digital calipers it can difficult. Some fittings are 3/8″, some are 22mm, some are 14mm on the inside diameter (some need to be 15mm), sometimes you’ll find fittings going off British pipe thread standards and some are labelled QC F or QC M to confuse.

Let’s take a deeper look what all the size mean on fittings.

How to Measure Connections and Fittings

To proper measure the fitting you need will require calipers. A measuring tape will work but it won’t be as good because we are talking about 1mm differences.

Here are the best calipers:

Here are some other things to know about when talking power washer adapters:

Male (M) vs. female (F) connections

The male side has a pin or plug that is inserted in the female socket or hole. The female fittings receives and holds the male connector in place.

NPT vs. BPT/BSP pipe thread standards

- NPT = National Pipe Thread. U.S. technical standard for screw threads.

- BSP = British Standard Pipe. British technical standard for screw threads.

Why should you care about NPT and BSP?

Because sometimes a pressure washer coupler will be NPT and sometimes it will be BSP. They don’t mesh together.

For example: a 3/8″ pipe size according to NPT has a thread pitch of 0.05555 inches (1.411mm) and an outer diameter of 0.675 inches (17.145mm). That same 3/8″ pipe according to BSP has a thread pitch of 0.0526 inches (1.337mm) and outer diameter of 0.6560 inches (16.662mm).

They are close but not exact and you won’t be able to turn a 3/8″ male NPT screw connection onto a 3/8″ female BSP connection more than a 3 or 4 turns before it locks up.

Internal vs. external diameter

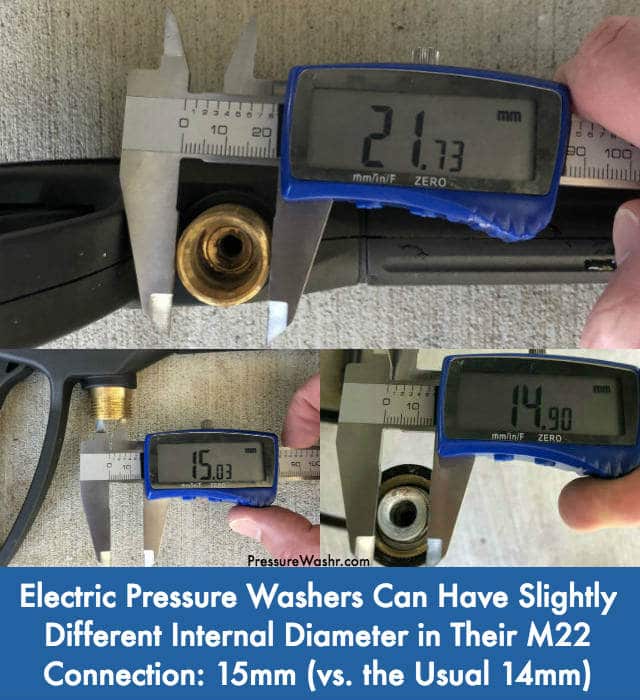

When measuring you’ll need to be mindful of both the internal and external diameters of the fitting. M22 screw connections on gas pressure washers will have 14mm internal diameter but the same M22 on an electric will have 15mm ID.

The Different Sizes You’ll See: M22 Threads, 3/8″ Threads and Quick Connects

The main fitting sizes seen are pictured below with digital calipers to show their dimensions.

M22 threads are common on pumps, hoses and spray guns

The outer diameter is 22mm, the inner diameter is 14mm and the inner plug on the female M22 side is 14mm. The female side has the o-ring to prevent leaking.

It should also be noted that there is also an M22 used on electric pressure washers, but it has a 15mm internal diameter.

3/8″ BSP Thread size

This is a British Standard Pipe thread (BSP) naming convention. It is the imperial name of the fitting size but not the size of the fitting (yes, weird). The actual size of the major diameter of a 3/8″ BSP thread is around 16.66mm (~2/3-inch).

Quick Connect Plug and Socket Sizes

All the quick connects we’ve seen have been 3/8″ QC. You don’t need to get the calipers out for the quick connects.

4 Examples to Show Fittings in Use

Now that you know the types and sizes of fittings, adapters and couplings let’s look at examples (with pictures) of them in everyday use.

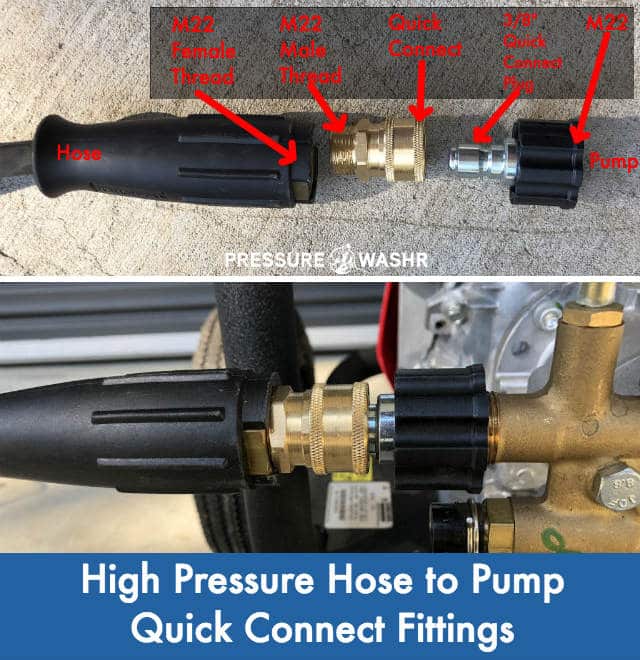

1.) Quick Connect Fittings to Make Connecting High Pressure Hose to Pump Quick and Easy

In this example you can see how a M22 style hose connection pressure washer hose can be made into a quick connect with a single fitting – a M22 male thread to female 3/8″ quick connect socket. Then you attach a fitting with a male quick connect plug to the pump outlet and you’re set.

Check it out:

2.) Dual M22 Male Coupling to Extend Length of Two High Pressure Hoses

Use this simple coupling to connect two M22 female connection hose ends. It make it so you don’t have to move your pressure washer all the time as you have more leeway with the longer hose.

Check it out:

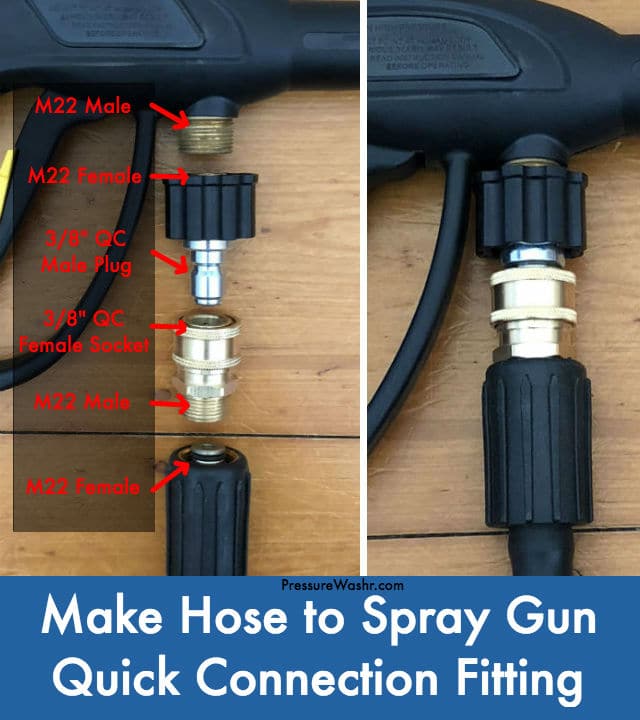

3.) Make Hose to Spray Gun Quick Connect

This is the same two fittings used in example #1 except at the spray gun end. The 3/8 inch QC couplings allow for much quicker install and exit of the spray wand from the hose when needed.

See it fit together:

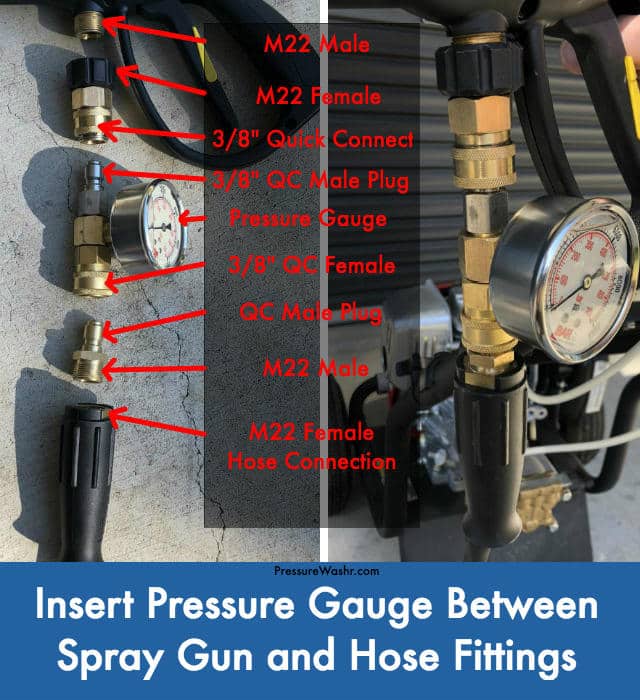

4.) Multiple Fittings to Insert Pressure Gauge Between Spray Gun and Hose

We test the pressures on the pressure washers so we need a pressure gauge inserted into the assembly. The pressure gauge has quick connect fittings so the proper adapters are required to make the spray gun and hose quick connect.

It’s a beefy setup and usually insert it at the pump to decrease the weight at the spray gun:

Fittings on Electric Pressure Washers (Are They Different?)

Some residential electric pressure washers have custom (to that brand) fittings. So if you want to replace the spray gun or hose you’ll often have to replace it with the same brand.

Another thing to be aware of is when they do have M22 screw connection the internal diameter will usually be different than the M22 on gas.

See here (gas pressure washers will have M22 with internal diameter of 14mm):

The electric pressure washer coupler will have internal diameter of 15mm instead of 14mm. That means if you try to connect your hose from your gas machine to your electric the hose female fitting will have the 14mm o-ring and the electric spray wand will have 15mm internal diameter. There’s 1mm of space – it will leak.

What Fittings, Couplers and Adapters are Best to Own?

There are two types of fittings that are must owns (in our opinion). The quick connect couplers and gun swivels. Both make pressure washing more enjoyable and easier.

Quick Connect Couplers

Quick connects make it so much easier to attach and detach the hose from the spray gun and the pump. With the screw connection it takes 15 seconds longer and is hard to do with only one hand. All-in-all for only a couple bucks you can make your life easier.

See best couplers on Amazon here…

Gun Swivels

Gun swivel fittings are great. They prevent and unkink the hose, which is amazing. You’ll know what I mean if you’ve ever dealt with 50-feet of hose. Wrangling the hose when pressure washing is avoidable. With a gun swivel.