Everything You Ought To Know About CARB Compliant Small Off-Road Engines

Do you like breathing clean air?

Do you like clear blue skies?

Do you live in California?

Yes, yes and yes? Then you’ll love what the California Air Resources Board (CARB) has been doing since 1967 to protect you from the harmful effects of air pollution.

Today we are going to focus on what CARB is doing/has done to regulate small off-road engines (SOREs) like used on pressure washers, portable gensets, lawn mowers, leaf blowers and other residential lawn and garden power equipment.

Does CARB only care about small engines?

No. CARB compliant extends to all products sold in California (not just ones with small engines). Paints, deodorants and insect repellants, for example, must all be CARB compliant.

The manufacturer is responsible (not you) for obtaining certification of compliance.

There are many more details and regulations that we’ll get into below.

PressureWashr spent 48 hours investigating the California Air Resources Board (CARB) small off-road engine (SORE) regulations to help you make sense of it all.

The Gist of This Guide in 100 Words

- When something is CARB compliant it complies with the CARB (California Air Resources Board) emissions standards for the product.

- For a small off-road engine (less than 25 horsepower and spark ignited) the manufacturer must design an emission control system to stay below CARB standards for certain pollutants (hydrocarbons, carbon monoxide, nitrogen oxides, particulate matter and reactive organic gases).

- Small engine emission control systems are as follows:

- Exhaust system: Modified carburetors, engine modifications, oxidizing catalyst mufflers, fuel injection systems, electronic engine control modules.

- Fuel/evaporative system (fuel tank, fuel lines, diurnal vapors): Special treatments for non-metallic fuel tanks, low permeation hoses, carbon canister/charcoal canister in gas cap.

Jump to a section:

- What is CARB compliant

- CARB vs. non-CARB small engines

- Standards enforcement and penalties

- The Best CARB compliant pressure washer

What is CARB Compliant?

Reminder:

- CARB equals California Air Resources Board.

- SORE equals Small (25 HP or less) Off-Road (Spark Ignition) Engines.

CARB History

CARB was started in 1967 with the merger of the Bureau of Air Sanitation with the California Motor Vehicle Pollution Control Board. It was approved by Ronald Reagan in an effort to combat pollution (smog) in California particularly the south-west basin (LA and surrounds). Reagan also approved the Federal Air Quality Act of 1967 to give California the right to go above and beyond federal air quality standards and to start studies and monitoring of air pollution.

From 1967 to 1970 studies and monitoring of air pollution went on. Then in 1970, the Clean Air Act was passed to allow regulation to limit emissions.

In 1977 and 1990 there were amendments made to expand the enforcement authority and allow for control of more types of pollutants.

The 1990 amendments forced the EPA (U.S. Environmental Protection Agency) to study how much SORE polluted. The study concluded that SORE should move towards emission reductions because it contributed as much as 10 – 20% of pollution.

SORE Emissions Include

- Hydrocarbons (HC) – Form ground level ozone or smog

- Particulate matter (PM) – Cause respiratory damage

- Nitrogen oxides (NOx) – Form ground level ozone and acid rain

- Carbon monoxide (CO) – Poisonous

- Carbon Dioxide (CO2) – Greenhouse gas

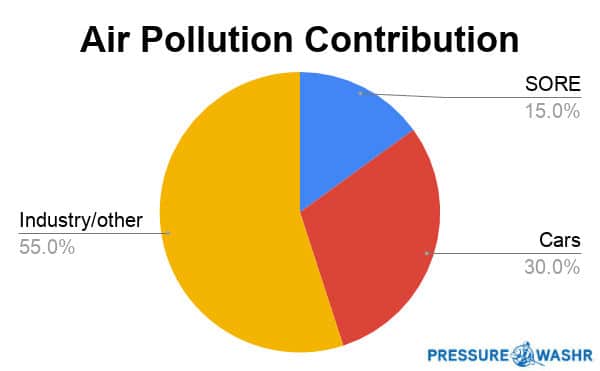

Depending on data sources, SORE contributes 10 – 20% of air pollution in cities of the U.S.A.. Cars are around 30% and industry/other (power plants, paints, solvents etc.) about 55%. See this pie chart for reference:

This may be hard to believe considering how many cars are on the road vs. small off-road engines like used in gardening equipment. But you have to realize cars have been under regulation since 1975 and small engines have zero emissions enforcement until 1997 model year engines. So they had/have lots of catching up to do.

CARB Regulation Rollout

Both EPA and CARB decided on a three-phase rollout of increasing emission reduction. EPA went with calling it Phase 1, 2 and 3. And CARB went with Tier 1, 2 and 3.

The 3 step rollout went as follows:

- Tier 1/Phase 1 would create an emission standard for SORE manufacturers to begin implementing on 1997 engine model years.

- This caused all SORE manufacturers to switch from 2-stroke to 4-stroke engines.

- Tier 2/Phase 2 would increase requirements for emission reduction starting on 2001 engine model years.

- This caused SORE manufacturers to improve carburetion and also include a vent line from the valve cover to the air intake to burn off fumes.

- Tier 3/Phase 3 would make requirements more stringent for 2011 and onwards engine model years.

- This one caused SORE manufacturers to further improve their carburetor and exhaust systems. Some included catalytic mufflers and some modified/improved fuel delivery. Also quite a few engine families already met Tier 3/Phase 3 standards during Tier 2/Phase 2 testing, and required no changes.

That’s the gist of how CARB and EPA rolled out the SORE emission standards. However, it should be noted CARB has more stringent emission standards than EPA for SORE.

What are the Details of the CARB SORE Emission Standard?

Manufacturers have to prove their engine pollutes less than the CARB standard allows.

CARB uses categories to make it simple and fair for different engine sizes in the small engine realm ( <25 HP).

SORE were divided in size categories for exhaust and evaporative emission testing as follows:

- Exhaust emission groupings:

- <=50cc

- 51cc to 80cc

- 81cc to 224cc

- >=225cc

- Evaporative emission groupings:

- <=80cc

- >81cc

There are also some deeper categories by engine model years, handheld vs. non-handheld etc. but we’ll ignore those for the sake of streamlining this article.

Pollutants tested for and units of measurment

Within each of the above engine emission groupings the engine must be tested to meet or beat CARB standards for pollutants (hydrocarbons, nitrogen oxides, carbon monoxide, particulate matter and reactive organic gases).

During the testing, pollutants from the SORE are measured in:

- Grams per kilowatt-hour: Hydrocarbons + Nitrogen Oxides, Carbon Monoxide and Particulate Matter

- Grams of reactive organic gases per square metre per day: Fuel hose and tank permeation

- Grams of Hydrocarbons: Diurnal vapors.

If you want to see the actual values of pollutants allowed there are two good tables provided by the EPA to give you a good idea:

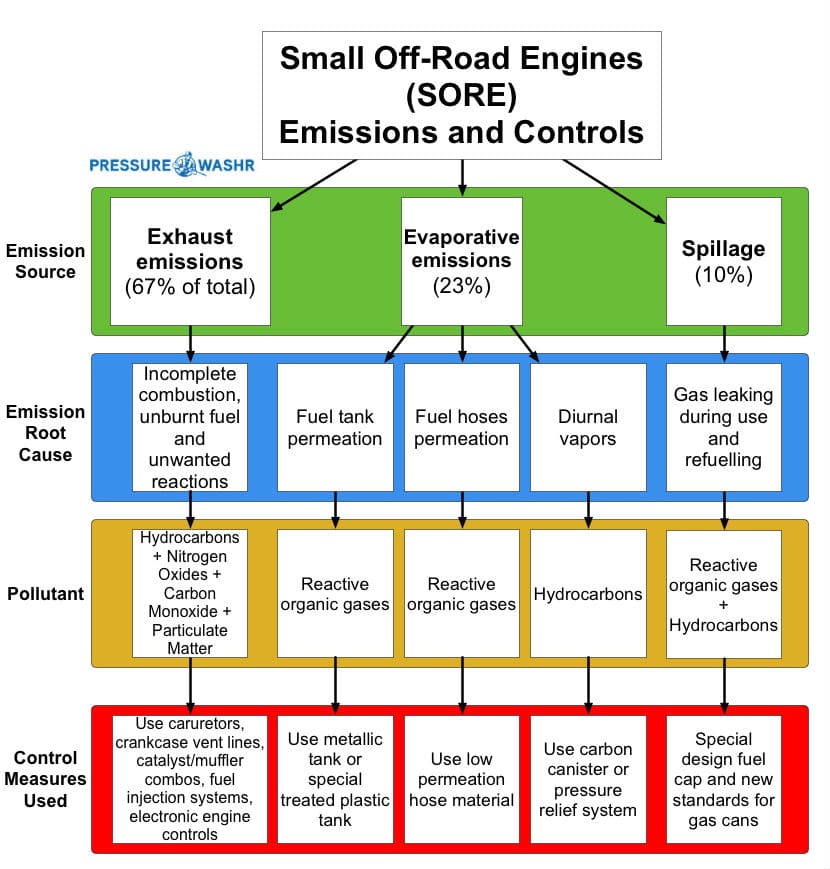

Flow chart of SORE emission control systems

Here is a flow chart that makes it easy to understand all the emissions and controls required for SORE manufacturers:

How Does a SORE Manufacturer Get Their Engine Certified CARB Compliant?

There’s two types of companies concerned with CARB compliancy: small engine manufacturers and manufacturers of equipment that has small engines. The small engine manufacturer has to go through the testing of the engine to get certified. The equipment manufacturer has to prove they are using previously certified engines and components (or go through the process to get their own components certified).

Here are the steps to CARB certification (all documents and rules/details on the CARB website):

- Register with EPA and CARB

- Group engines into exhaust families (cc’s, # cylinders fuel system, cooling system etc.) and evaporative families (fuel tank design, purge strategy etc.)

- Test engines for compliance and record results (third-party or in-house)

- Submit documents and paperwork to CARB and EPA

- If engines passes: Receive a Certificate of Conformity from EPA and Executive Order from CARB

- Label each engine as required

- At this stage, manufacturer can start selling product in California

- Get EPA and CARB approval before all engine changes

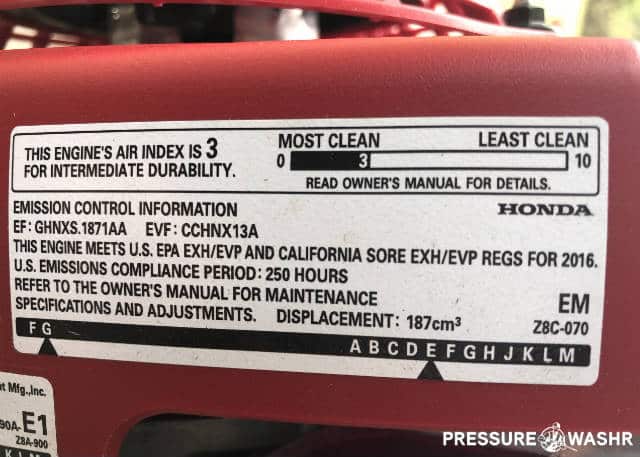

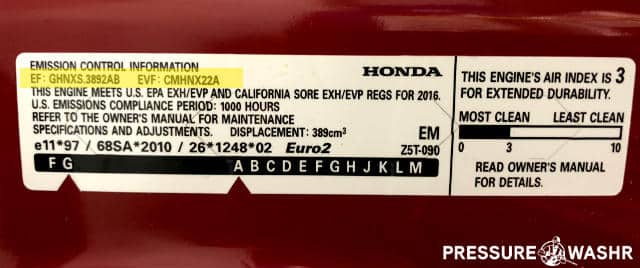

What an EPA and CARB approved engine label looks like (from Honda GC190 on a pressure washer):

And here’s the label from a Honda GX390 on a 4,000 PSI, 4 GPM power washer:

See the highlight?

EF is the engine family and EVF is the evaporative family.

Here’s how to read it:

EF: GHNXS.3892AB

- G = Model year code (G = 2016, H = 2017, J = 2018 etc.)

- HNX = Manufacturer code (HNX is Honda, BSX is Briggs & Stratton, YMX is Yamaha)

- S = Industry sector code (S = small non-road spark-ignition engines)

- .389 = Engine displacement code (.389 is 389 cc)

- 2 = Engine class (2 = Nonhandheld equipment engine greater than 225cc)

- AB = Manufacturer own name for this engine family

EVF: CMHNX22A

- C = Venting control type (C = carbon canister, S = Sealed tank)

- M = Tank barrier type (M = metal, P = treated plastic, C = co-extruded, L = selar, N = nylon, A = acetal, O = other)

- HNX = Manufacturer code (HNX is Honda)

- 2 = Engine class

- 2A = Unique identifier for manufacturer use

CARB Future Goals

CARB wants to reduce air pollution. Not just from SORE but from all sources. And they have. It was said that in the 90s you couldn’t see the Hollywood sign on most days due to smog. Now you can see it on most days.

CARB estimates there are ~17 million small engines in California (most on lawn and garden equipment). Their estimate is accurate because small engine makers (Honda, Toro, Husqvarna, Briggs & Stratton, Yamaha etc.) have to provide their California unit sales data to CARB.

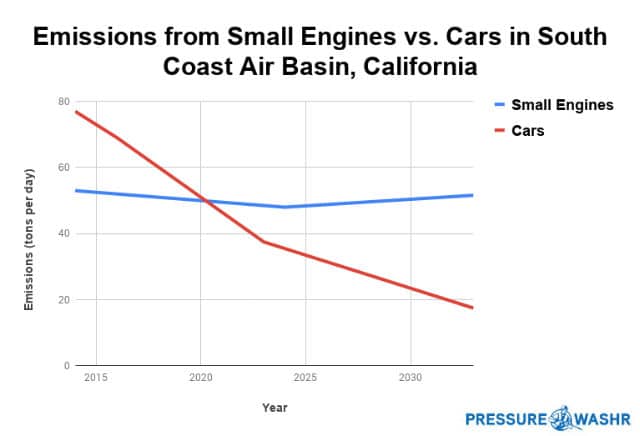

CARB claims to have made SORE 50% cleaner since CARB SORE Tier 1 regulations were implemented for 1997 engines. However, due to increasing efficiency and technology used for emission control in cars, CARB experts believe SORE emissions will pass car emissions in 2020.

See this graph to visualize emissions from small engines vs. cars in Southern California Air Basin:

Promoting zero emission equipment (ZEE)

CARB has been aggressive promoting electric power equipment to help meet its future goals of lowering SORE emissions.

Further regulation

In addition to promoting electric power equipment they plan on further regulatory measures and incentives to get you to buy newer model small engines compliant with stricter emission standards.

CARB and EPA have both started implementing a Tier IV and Phase 4 program for non-road large spark ignition engines and will begin rollout for SORE in 2020 with a goal to reduce their emission a further 80% by 2031.

CARB Compliant Engine vs. Non-CARB Compliant – What are the Differences?

The #1 Main Difference

A CARB compliant SORE has gone through the process to get an Executive Order from the CARB certifying their engine family (families) as being compliant to their standards.

A “non-CARB compliant” SORE may actually meet CARB emission standards but they have not gone through the certification process to get the Executive Order from CARB – so they lose out on all the California sales.

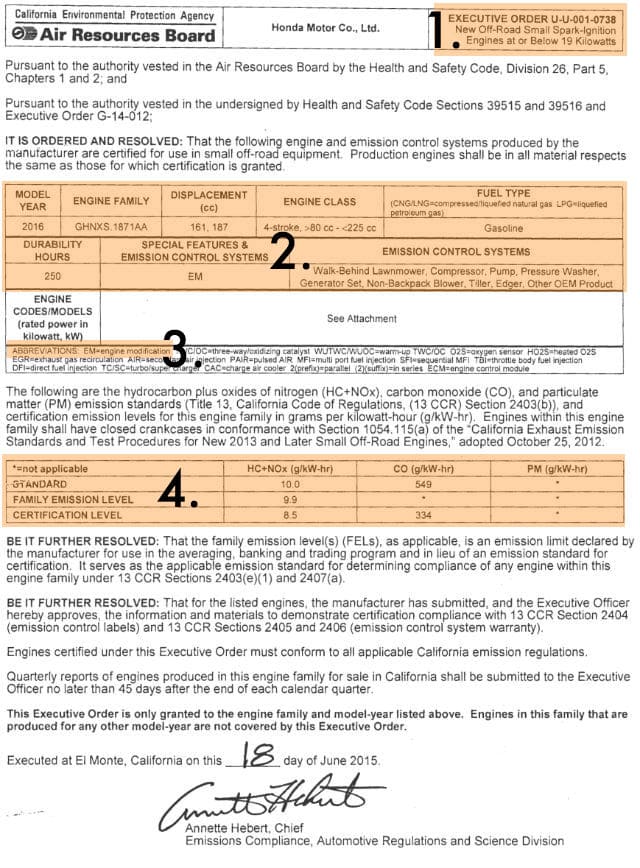

Here is the Executive Order from CARB for the Honda GC190 (the engine on the Simpson Megashot pressure washer). Once an engine family receives the Executive Order it is certified CARB compliant.

1. Executive Order details

2. Engine family details

3. Emission control systems (EM = engine mods)

4. Emissions test results data

Emission Control Systems

A CARB compliant SORE is not inventing any new technology. The changes are happening because they are now being regulated to include the technology that has already been invented to reduce car emissions. Cars have been regulated by EPA and CARB since 1975. The reason SORE are causing a disproportionate amount of pollution is because they had zero regulation until 1997 model years.

To comply with EPA and CARB emission standards, SORE engine and equipment manufacturer engineering departments have come up with different solutions.

Let’s explore the different ways by looking separately at the exhaust and fuel systems.

Limiting Exhaust Emissions

The reason an engine fails the exhaust emissions portion of the CARB testing is because it fails to manage or prevent certain pollutants from being created and being released to air in amounts over the CARB standard allowances.

The root cause is incomplete combustion, unburnt fuel and unwanted reactions in the combustion chamber leading to pollutants of hydrocarbons, nitrogen oxides, carbon monoxide and particulate matter.

Engine manufacturers either want to prevent pollutants being created in the first place or manage/treat the pollutants before being released to environment in allowable amounts.

Preventing/minimizing pollutant creation

Most engine makers decide to go this route and minimizing pollutant creation in the combustion process.

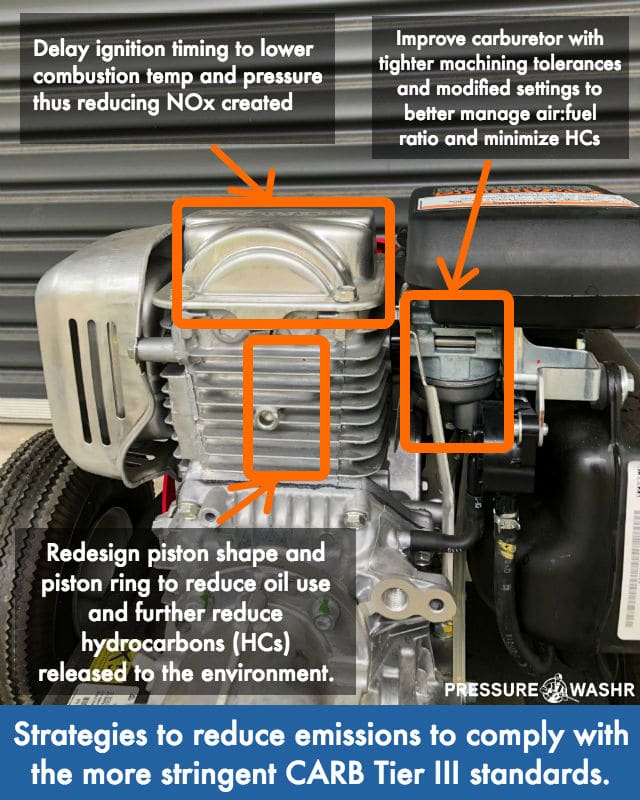

Here are some of the strategies that have worked:

- Use improved carburetor (most common). Tightening up the machining tolerances and modifying the carb settings allows it to more accurately manage the air-fuel mix ratio and minimize unburnt fuel and incomplete combustion.

- Engine modifications. Some manufacturers have redesigned piston shape and piston ring to reduce oil use and thus hydrocarbon emission.

- Engine adjustments. By delaying ignition timing the combustion happens at a lower temperature and pressure reducing amount of smog causing nitrogen oxides created.

- Use fuel injection systems to deliver fuel in more precise amounts into the cylinder at high pressure. This further decreases the amount of unwanted pollutant byproduts because the combustion process is closer to ideal (instead of running lean or rich).

- Use an electronic engine control unit (ECU) combined with multiple sensors to manage the air-fuel ratio, idle speed and valve timing to ensure a stoichiometric ratio (everything is consumed in a perfect reaction).

Managing pollutants

Here’s some strategies that have been used to gain CARB certification:

- Use crankcase vent lines (most common) to return unburnt fuels and created pollutants back to the intake manifold to be mixed into the air and burnt in the combustion process.

- Use catalyst in muffler to react with the pollutants to reduce nitrogen oxides into nitrogen gas, oxidize carbon monoxide into carbon dioxide and oxidize hydrocarbons into carbon dioxide and water vapor.

Limiting Evaporative Emissions

The reason an engine fails the evaporative emissions portion of the CARB testing is because it allows too much permeation of fuel vapors from the fuel lines, fuel tank and diurnal pressure changes (expansion and contraction of fuel in the tank). These processes allow reactive organic gases and hydrocarbons into the environment.

Here’s how SORE manufacturers prevent and/or minimize this pollution:

- Gas tanks: Use metallic gas tank or special treatments for plastic or other non-metallic tanks.

- Fuel lines: Use CARB certified low permeation fuel hose materials.

- Diurnal vapors: Use carbon/charcoal canister or pressure relief system.

Cost Differences

CARB compliant power equipment will usually be more expensive than non-CARB certified because of the SORE manufacturer having to pay for testing, certification and continual compliance to CARB standards.

The cost difference in engineering a lower emission engine will only be seen upfront and will be minimal.

The physical engine build cost difference is minimal, and over the production of the engine, surely nil/zero.

Performance Differences

The performance differences are minimal across the board. Non-CARB will have slightly more power (1-3%) and the CARB approved one will have slightly better fuel economy.

How Does CARB Enforce Compliance of Their Regulations?

The penalties are harsh for noncompliance but CARB and SORE manufacturers work together to avoid the need to violate the regulations.

Programs to Help SORE Manufacturers Comply

CARB and SORE manufacturers work together to reduce emissions. Together they understand the importance of the regulations and together they are understanding of the difficulties.

CARB has two programs to provide some leniency to small engine manufacturers and downstream equipment makers with regards to transitioning to more stringent emission controls.

1. Averaging, banking and trading program

This program allows SORE makers to use gained emission credits from tested engine families that go above and beyond emission standards to help worse performing engine families still get certified. It also allows flexibility in new engine release dates.

- Averaging: Trading emission credits between engine families

- Banking: Stockpiling emission credits for future use

- Trading: Exchanging emission credits between SORE companies for use in averaging

2. Flex-engines program

Another credits program. But this one is for downstream equipment manufacturers – ones that buy small engines for use in/on their product.

The program gives flexibility and allows for a certain percentage of their most popular/important equipment to use older CARB approved engines during new regulation eras (Tier I engines after Tier II is already in effect). This allows them a transitioning period to implement new SORE designs for their products. For example, a new exhaust system if the engine manufacturer is shipping without.

How Does CARB Monitor and Enforce Their Regulations?

CARB has an enforcement policy that gives the details of their penalties and enforcement methods. Let’s explore them.

Tamper proofing

Tampering with the emission control system is a violation of Federal and California Law.

In addition to a law, CARB has methods described in their regulation to further deter tampering of emission control systems, including:

- Special plugs

- Limiting caps

- Need for custom tools to tamper

- Need for special tools to access areas needed to adjust things.

Production line testing (PLT)

To ensure manufacturers don’t test a one-off custom engine to pass emission testing CARB requires quarterly production line testing. Four times a year random engines come off the production line to be taken for emission tests with results being sent to CARB compliance department.

As part of PLT, CARB also reserves the right to show up at the manufacturing facility to perform tests or grab random engines off the line for testing off-site by a third-party.

Penalties

The requirements for SOREs sold in California are as follows:

- Have a valid Executive Order

- Have correct emissions labels

- Provide warranty for emission control system parts.

CARB enforces with:

- Field inspections

- Emission testing

- Audit testing

- Self disclosure.

Max Penalties for Non-Compliant SOREs in Cali are:

- $500 per engine in violation

- $50 per test procedure violation.

In 2010, CARB collected $398,348 in penalties in the small off-road engine category.

Sources:

Please refer to our sources for further information.

- Small Off-Road Engines (SORE) Hub Page. www.arb.ca.gov.

- Small Engine Fact Sheet June 2017 (1-page PDF). www.arb.ca.gov.

- Final Regulation Order Test Procedures – Small Off-Road Engines (53-page PDF). October 25, 2012. www.arb.ca.gov.

- SORE Evaporative Certification FAQ’s (16-page PDF). November 9, 2015. www.arb.ca.gov.

- CARB compliant or not? Posted to ArboristSite forum on March 24, 2013 by KenJax. www.ArboristSite.com.

- EPA and CARB Emission Standards To Control Nonroad Exhaust Emissions of Fire Pumps and Chain Saws. Written by Lois P. Sicking and Mark Zavala. www.fs.fed.us.

- Left-coast gamble: CARB’s enforcement potential, narrow compliance alternatives. Posted on September 30, 2013 by Todd Dills. www.OverdriveOnline.com.

- Small Engine Testing. ESWAmerica.com.

- Are regulations killing our industry? Part I: Emissions regulations. By Gina Kellogg Hogan. www.Grounds-mag.com.

- Outdoor Power Equipment Institute. OPEI.org.

- Victorian Marine Industry to Assist Busineses Understand Small Engine Emissions and Evaporative Laws. Posted on June 28, 2016. www.BlueSkyAlliance.com.au.

- Emissions Education. Posted on May 1, 2012 by Pam Meyer. www.ForConstructionPros.com.

- List to Determine Preempt Off-Road Applications. April 4, 2014. www.arb.ca.gov.

- ARB Small Off-Road Engine Emissions Certification PowerPoint Presentation. November 9, 2015. www.arb.ca.gov.

- Federal Register EPA Control of Emissions From Nonroad Spark-Ignition Engine and Equipment; Final Rule. October 8, 2008. www.gpo.gov.

- Small Engine Repair: Checking a Vacuum Fuel Pump / Fuel System on a Kohler V-Twin Engine. June 4, 2011. YouTube.com.

![[Solution] My Pressure Washer Loses Pressure When the Trigger is Pulled](https://pressurewashr.com/wp-content/uploads/2021/06/Losing-Pressure-Thumb-768x453.png)