How to Troubleshoot Pressure Washer Problems Like a Mechanic

Here’s how we know what they are:

- Reading 300+ emails from pressure washer users asking for help to solve their machine’s issues and counting the occurrences of each fault in an Excel spreadsheet.

- Going through 16 popular pressure washer brands’ Operating Manual and tabulating the troubleshooting sections’ listed problems and solutions.

- Looking through my power washer logbooks over the last 8 years to see the most common issues.

After spending 14+ hours gathering the data the common faults could easily be broken down into 5 sections: Water pressure problems, water leaking issues, gas machine specific problems, electric pressure washer faults and other common problems. From there the troubleshooting tips are broken down to 3 columns: What’s wrong, most likely cause and how to fix.

Quick note:

- Always check your Operator’s Manual for troubleshooting tips and safety first. Be aware many of the problems have 5 or more possible solutions for you to try.

Summary Table of Troubleshooting Tips:

The goal of this entire page is to make the most useful pressure washer troubleshooting guide on the internet. We constantly update and improve this table. It was last updated July 11, 2023.

| What's Wrong? | Cause | How to Fix |

| 1. Low pressure | Insufficient inlet water supply | Unkink garden hose, ensure full water pressure coming from tap, use large enough diameter garden hose (see manual) |

| Blocked inlet water filter | Remove garden hose connection and remove debris | |

| None or incorrect nozzle | Ensure correct nozzle being used | |

| 2. No pressure | Damaged unloader valve | Adjust unloader screw, check for damaged seals/springs |

| Damaged pump inlet valves/manifold | Disassemble pump and replace/clean components of inlet manifold | |

| 3. Pulsing pressure (high then low) | Damaged pump inlet valves/manifold | Disassemble pump and replace/clean components of inlet manifold |

| Faulty pump | Replace pump | |

| Pump sucking air | Turn off machine (but not water supply) and release pressure by squeezing trigger gun | |

| Obstructed nozzle, water inlet filter or gun/spray wand | Use needle to clear nozzle, fresh water to flush water inlet and vinegar to clear any deposits in gun/wand | |

| 4. Spiking pressure | Poorly calibrated unloader valve | Adjust unloader to proper pressure as per manual |

| 5. Pressure drops after a few seconds use | Nozzle blocked | Clear nozzle with needle |

| Issues with unloader valve | Remove unloader and clean/repair | |

| 6. Pressure washer isn't cleaning the surface | Using wrong nozzle | Switch to higher pressure spray nozzle |

| What's Wrong? | Cause | How to Fix |

| 7. Water leaking from pump | Seals broken, cracked or worn | Return and replace under warranty |

| Loose bolts on pump assembly | Tighten bolts to ensure pump casing properly sealed together | |

| Thermal valve activated | Wait 5 minutes before using (it will de-activate once cool enough) | |

| 8. Water leaking from garden hose connection | Broken or improper connection | Connect properly |

| Broken rubber washer | Replace | |

| 9. Water leaking from spray wand or connections | Broken o-ring inside hose connection | Replace o-ring or return hose for new |

| Not properly connected | Connect properly | |

| What's Wrong? | Cause | How to Fix |

| 10. Engine will not start | No gas | Fill with gas |

| Choke is wrong position | Move to correct position as per manual | |

| Pressure build up | Squeeze trigger gun to release pressure in system | |

| Spark plug wire not connected | Connect wire | |

| Faulty spark plug | Replace with new | |

| 11. Engine stops running while in use | Low oil level | Check and fill oil |

| Dirty air filter | Clean or replace it | |

| 12. Engine not providing enough power | Dirty air filter | Clean or replace |

| Engine not running at correct RPM | Adjust RPM to engine specs with pump detached | |

| 13. Oil dripping from engine | Worn seals | Replace seals (covered by warranty) |

| 14. Water in oil - looks milky | Worn or broken pistons allowing water through | Repair engine through warranty |

| Worn seals | Replace seals (covered by warranty) | |

| What's Wrong? | Cause | How to Fix |

| 15. Machine won't start | Electric outlet is faulty | Check main fuse, check plug |

| Not plugged in | Plug in | |

| Faulty motor | Return under warranty | |

| 16. Motor stops running while in use | Low voltage | Check voltage is within motor specified range |

| What's Wrong? | Cause | How to Fix |

| 17. Chemical/detergent injector not working | Using wrong nozzle | Insert black soaping nozzle on wand |

| Soap tube inlet filter clogged (hose end that sits in soap bottle) | Flush with fresh water | |

| Soap inlet valve is clogged or blocked (pump side of tube) | Remove hose and use small Allen key to push through hole to remove debris/unstick the ball valve | |

| Detergent mixture is too thick | Add more water to dilute | |

| 18. Irregular bypass causing pressure fluctuations (sometimes) after use | Worn or broken unloader valve seals, springs or other components | Remove and replace |

| Unloader valve not properly installed | Remove and install correctly, properly seating the valve at the bottom of the pump housing | |

| Water leaking from unloader valve | Replace worn or broken seals and re-install unloader valve to specification | |

| Dirt in unloader | Remove and clean | |

| 19. Excessive noise | Water intake is blocked | Check and clean or replace |

| Not enough oil in engine | Check and add oil | |

| Not enough oil in pump | Disassemble and check (if possible) and add oil, otherwise return under warranty | |

| 20. Oil leaking from pump | Loose bolts/fitting | Check and tighten |

| Damaged parts like seals or pistons | If comfortable disassemble to check, clean and replace, otherwise return under warranty | |

Instructions How To Correct The Tricky Issues

In this section are instructions how to fix the tricky pressure washer issues, namely the ones that require you to tear down the pump.

The Lazy Man’s Way to Diagnose Water Pressure (No Pressure) Issues

Here’s the 5 step approach to solving 95% of water pressure issues in 10 minutes or less:

- Check water supply: Open the water supply valve to full to ensure the pump is getting enough flow.

- Check hose for kinks: I can’t tell you how many times I’ve tested a pressure washer, got everything going, only to pull the trigger have it not reach pressure. I check the inlet for blocks. I check the nozzle. I check the water is on. And after all these things check out and it’s still not working I turn it off to read through the manual to find out what I’m doing wrong. Then, all of sudden, I notice a kink in the hose and realize how much an idiot I was not to notice. I fix the kink start the machine and it all works fine. Don’t make this mistake – always check for kinks.

- Release air from system: Always connect the garden hose to the power washer first. Then turn the water tap on and pull the trigger gun to release water from the system at the garden hose water pressure before starting the engine or motor. This will release all the pressure from the system and allow the pump to function.

- Ensure correct nozzle and nozzle not clogged:

Use a needle to clear the nozzle tip of any debris. Any blocks at the nozzle will cause decreased flow and increased pressure in the systems, possibly triggering the unloader to enter bypass.

Everything You Need to Know About Removing the Unloader Valve to Check for Issues

Unloader valves allow water to run through the pump when you are not holding down the trigger on the pressure gun. If there was no unloader valve then pressure would build inside the system (when not in use) so when you did pull the trigger it would stall the engine or explode a weak link part – probably the pressure hose o-ring.

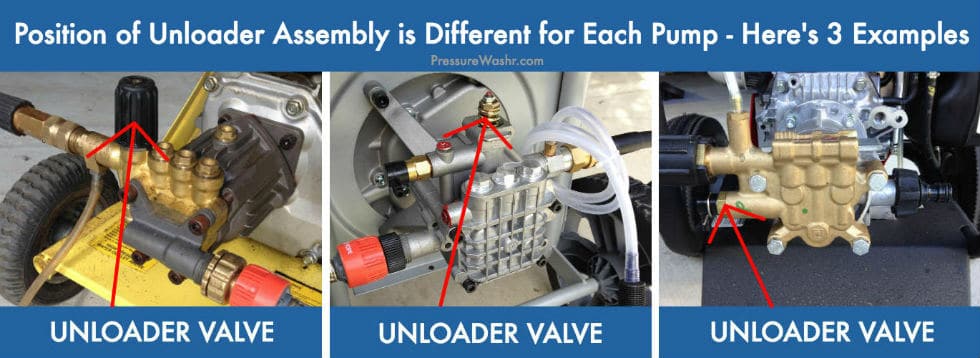

Check out where the unloader is located on 3 different pressure washer pumps:

As you can see the unloader is located on the exit side of the pump because it allows the pressurized water to flow back through the pump when it isn’t exiting into the high pressure hose (you’re not pressure washing anything).

Take a look at two different disassembled unloader valve assemblies:

The one on the left is from the Stanley gas pressure washer also shown in the above image on the left. It is a flow actuated unloader.

The unloader on the right is from an AR Blue Clean electric pressure washer. It is a pressure actuated unloader.

Both these assemblies can be taken out of the pump for cleaning and repair, without damaging them.

The Difference Between Flow and Pressure Actuated Unloaders

- Flow actuated – As the name suggests, these unloader valves respond to water flow stoppage. When there is no flow leaving the nozzle the valve will “open” allowing water to flow back to the pump inlet.

- Pros: Safer because doesn’t require pressure build up.

- Cons: More sensitive to system issues like a clogged nozzle, incorrect nozzle orifice size and other flow problems.

- Pressure actuated – Instead of responding to flow, this type of unloader is forced open by an increase in water pressure allowing water to bypass back to pump inlet (this pressure is increase is usually caused by flow stoppage).

- Pros: Less sensitive to flow issues within the system because it responds only to trapped pressure on the outlet side of the pump.

- Cons: Less safe because it needs pressure rise to work (could cause failures within system).

Troubleshooting the Unloader Valve

Many pressure problems begin and end at the unloader. A cracked o-ring, dirt caught in the spring or a stuck shaft are the most common issues solved by simply removing the unloader and cleaning/looking for issues.

Sources

- “Troubleshooting Pressure Washer and Power Washer Problems.” www.PressureWasherTroubleShooter.com

- “Hammer History.” Wikipedia.org

- “All About Unloader Valves.” www.ePowerWash.com