How to Maintain Your Pressure Washer to Keep it Running Smooth

Today you’re going to learn everything there is to know about pressure washer maintenance services:

- When to perform maintenance including a schedule

- How to do each maintenance task step-by-step, and

- Servicing tips specific for electric and gas pressure washers.

But first:

Why should you bother doing regular service tune-ups?

Why Perform Routine Maintenance?

5 Reasons:

- To prevent breakdowns

- To avoid costly repairs

- To avoid inconvenience

- To ensure it performs consistently well

- To ensure it withstands 100s of hours of use.

Best Case Scenario

You wake up Saturday morning, have a fresh cup of coffee, a slice of toast and a couple eggs and then go outside for a sunny day of satisfying pressure washing.

You wheel the gas pressure washer to the area being cleaned. You do the routine maintenance checks, hook up the garden hose and turn the water on. You move the engine stop switch to the on position, adjust the choke and pull the starter…

And the engine comes alive first try and the pump provides reliable pressure and flow to get the job done no problems.

Worst Case Scenario

Spending Saturday rushing/calling around trying to figure out a fix for a broken-down-won’t-start gas pressure washer because you have friends coming over for a BBQ and the back patio is a moss and mildew nightmare.

What You Need To Do

A gas pressure washer is not like a car where you go months without opening the hood and checking fluid levels. A power washer needs love and care.

The best way to make sure your pressure washer starts and runs smoothly every time is by performing routine maintenance – before and after each pressure wash.

This guide walks you through everything you need to know about performing routine pressure washer maintenance tune-ups (even if you’ve never serviced a power washer before).

Pressure Washer Maintenance Schedule

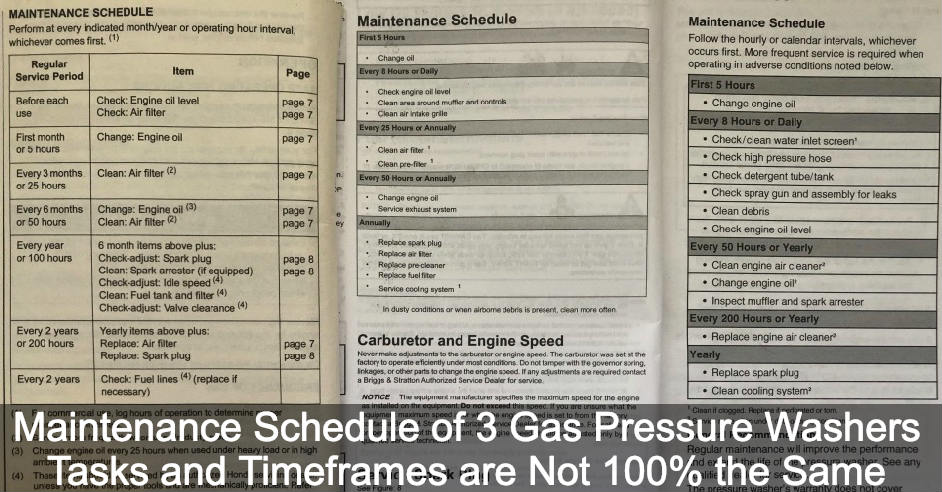

Here’s a photo showing the Maintenance Schedule of 3 different gas pressure washers. It shows you the tasks and timeframes are not 100% the same across the board, but they’re very similar.

If you can’t find your User Manual then use the below Maintenance Schedule because it has all the tasks required. It is for small gas engine powered machines.

The Maintenance Schedule is broken up into timeframes: before each use, after 5 hours use all the way up to after 200 hours use or every 2 years.

If you click the link in the ‘How To Guide’ column you’ll jump to the point on this page with the how to instructions.

Maintenance Schedule Checklist

| Before Each Use | Instructions |

|---|---|

| General inspection: - Check for oil leaks - Check for fuel leaks - Check for water leaks | See here |

| Check fuel level | See here |

| Check oil level | See here |

| Check pump oil level (if required, see manual) | See here |

| Check water inlet screen | See here |

| Check high pressure hose | See here |

| Check air filter | See here |

| After First 5 Hours Use | Instructions |

| Change engine oil | See here |

| 25 Hrs Use or Yearly (Whichever Comes First) | Instructions |

| Clean air filter | See here |

| 50 Hrs Use or Yearly | Instructions |

| Change engine oil (again) | See here |

| 75 Hrs Use or Yearly | Instructions |

| Inspect and clean spark arrestor and muffler | See here |

| 100 Hrs Use or Yearly | Instructions |

| Check, clean, adjust, replace spark plug | See here |

| 200 Hrs or Every 2 Years | Instructions |

| Replace air filter | See here |

| Replace fuel filter | See here |

| Check fuel lines | See here |

Step-by-Step How to Perform the Routine Maintenance Tasks

You’ll notice most of the maintenance service involves checking your pressure washer is in good shape. You almost never have to disassemble anything. And the tasks you have to manually do something – like changing the oil or spark plug – are easy and take 5 minutes.

Here are how to instructions for all the tasks (with step-by-step pictures).

How to Check for Leaks (and What to Do if You Find One)

Fuel/oil leaks

Before turning the pressure washer and mains water on take a close look for oil and fuel leaks. Look on the frame for drips, look at the fuel lines, on the engine for excess oil or fuel residue and the underside of the pump.

If you find a tiny amount of leakage then wipe it away and monitor it after each use. If it continues take it in to a repair centre for a thorough inspection.

Water leaks

You’ll want to check for water leaks after you turn on the mains water supply (low pressure) and during pressure wash use (high pressure).

How to Take Care of the Nozzles, Spray Gun, Hose and Water Inlet Screen

Nozzles

Check nozzle oriface for debris. Use unfolded paperclip or nozzle tip cleaner (taped to your User Manual) to push debris out of nozzle. Flush with water to rinse it away.

Spray gun

You’ll want to check the trigger part of the gun and the hose connection part. These are the two important parts for maintenance purposes. Check the hose connection for cracking and function (does it hold the hose securely?). Pull the trigger to ensure the spring back function is working correctly. Replace spray gun if needed.

Hose

Check for cracks, cuts, leaks and bulging of hose caused from kinking and wear. Replace hose if you find. If high pressure hose leaks it will be spraying water out at 2,000 PSI and poses a danger.

Inlet water screen

Where you attach the garden hose at the pump inlet check the water filter screen for debris and buildup. Clean (or replace) screen if necessary.

How to Check Fluid Levels

Fuel

It is recommended to fill fuel tank after each use to keep as much air out of it as possible. Some fuel tanks will have sight levels but most you will have to open the cap and look in. If you can’t see any fuel then you should fill it up with correct fuel.

Oil

To check the engine oil find the dipstick and pull it out and wipe it clean. Put back in without screwing. Now pull out again to check oil level on the dipstick and if it is low you will see the fluid mark on the stick marker. Fill with proper oil if required.

Pump oil (if applicable)

Most pressure washer pumps of worth will have a sight level. In terms of checking the quality you should follow the maintenance schedule checklist in your manual (or above).

How to Take Care of, Maintain and Replace the Air Filter

Check

The air cleaner keeps small debris from entering and damaging the carburetor and engine, which would cause premature engine wear and failure. To prevent this we’ll need to check and clean the air filter often – especially if you’re pressure washing in dusty areas.

Clean

To clean the air filter first remove it from it case. Hit it against a hard surface a few times to remove excess dirt. Wipe the air cleaner with a wet rag.

Replace

You can purchase air cleaner’s for small engines at most general auto shops or online here. Once you have it at home take the old one off and put your new one on. Simple.

How to Change Engine Oil

Remove oil spigot. Locate drain bolt. Place oil catch container below drain bolt. Unscrew oil drain bolt and allow oil to fully drain into container. Use funnel to fill engine with approved oil.

Tip: Empty oil after the power washer has been running. This ensures oil is warm and flows better to empty completely.

How to Change Pump Oil (if Required)

How to know if it needs changing

Some pressure washer pumps come factory sealed and you have no way to change the pump oil. In fact, 95% of power washers under $400 will not require any pump maintenance. Your manual will tell you this information.

Empty & Fill

Below is a video with the steps to change pump oil. The gist is to loosen off the fill bolt (at the top of pump) before removing the drain plug bolt (bottom). This reduces pressure and prevents the oil from initially spraying out at high pressure. Allow the oil to drain into a suitable container. Put drain plug back in and tighten. Fill pump with non-detergent pump oil to desired level (~85% full).

How to Perform Maintenance on the Exhaust System

The spark arrestor is what requires a service. The spark arrestor is hidden under the muffler protector. Remove the protector bolts. Remove the spark arrestor screws. Remove carbon deposits with a brush from the spark arrestor. If it has breaks or holes in the screen you’ll want to order a replacement. If not, then place it back and secure into position.

How to Maintain the Spark Plug

- Disconnect spark plug cap and blow away any dirt

- Use proper wrench to remove spark plug from engine

- Check it for damage and wear – fouled, washer is poor condition or electrode worn. Replace if needed.

- Check electrode gap is correct – adjust by hand if needed

- Put spark plug back in place by hand

- Tighten with proper wrench to complete installation.

What to Check for When Inspecting the Fuel Lines, Tank and Fuel Filter

Look for cracks and fraying in the fuel line. Look to see it is firmly connected at both ends and isn’t leaking. Check the fuel tank isn’t cracked or damaged.

Everything You Ought to Know About Pressure Washer Storage

Let’s look at the proper way to store your power washer after each use, for 30+ days and over winter.

After Each Use

Turning off

It’s important to run through a series of steps to ensure the power washer pump and lines are clear of water and detergent. This prevents minerals and trace dirt clinging to pump parts causing damage over time.

Here’s the shut down steps (follow these to avoid problems):

- If you used soap then remove black soap nozzle and replace with green or white spray tip. Now run the water through for 1 minute to remove excess soap from the system.

- Turn off engine. Now pull the spray trigger for 10 seconds to run the mains water through at low pressure. All good. Now turn the mains water off and again pull the trigger to remove any remaining water and pressure from the system.

- Disconnect pressure hose from spray gun and pump and mains water hose from pump. Roll up and drain water from pressure hose and place on hook for storage. Place nozzle and gun in storage place on machine.

- With everything disconnected pull the engine recoil a few times to further drain the pump of any liquid.

Storage location

After going through the above 4-steps you are now ready to roll your power washer to an area in your shed or garage for storing.

The best storage location is:

- Clean and dry

- Away from furnaces, dryers etc.

- Out of the way to avoid tripping or crashing into it.

Cover

A good fitting, protective, breathable cover will help prevent dust.

Long Term Storage

Do everything from ‘After Each Use’ section and also follow the below to keep your machine safe and ready to go when you need it in a few months.

Engine (oil and fuel)

Two options to protect the fuel system:

- Use a fuel stabilizer. If you plan to leave fuel in the tank over storage time then be sure to add a fuel stabilizer to prevent acid and gum deposits forming. Add the stabilizer then run the engine for a few minutes to circulate.

- Empty fuel. Tip pressure washer to get drain fuel into a container. Then run machine until it stops.

Do you need to change the oil before or after months of storage?

Change oil before storage. You don’t want to store it for months with old contaminated oil.

Pump

To protect pump over a storage period add pump saver. Pump saver fills the pump cavity and protects its pistons and seals from mineral deposits left by the water.

Once you have a pump saver product in hand attach it to the garden hose inlet. Press the button to release the lubricant into the pump until you see it squirting out the outlet. Now the pump is full of the pump saver and ready to store long term.

Winter Storage

Protecting from freezing temperatures

The idea here is to get 99.9% of the water out of the system so it doesn’t freeze inside the system.

We’re going to use pump saver in the pump for storing it…

But first we need to further drain the detergent system and clear everything again.

- Fill up detergent tank with water

- Attach black soaping nozzle to lance and pull trigger until detergent tank is empty of water.

- No go through normal shut down procedure as described above in ‘After Each Use’ section.

- Now add pump saver.

- Store as described in ‘Long Term Storage’ section.

Electric Pressure Washer Care and Maintenance

The 5 main benefits of an electric pressure washer are:

- Minimal maintenance

- Can use indoors (no fumes)

- More affordable than gas

- No need for fuel fill ups

- Quieter.

Without question electrics are more popular. Home owners find it easier to justify the purchase since they only need to use it once or twice a month (after the excitement wears off using it 10 times the first weekend). So ~$450 for a gas power washer seems too high.

Yes, gas powered will get the job done faster but for many the downsides overcome the benefits – engine maintenance time demand and 2-3x cost of an electric for a medium-duty machine.

Maintenance Required

A home-use electric pressure cleaner uses an electric motor (universal or induction) and has an axial or wobble piston pump. It has a closed lubrication system, so no oil addition is needed.

If the electric motor or pump stops working (and troubleshooting doesn’t work) it will be cheaper to replace than to repair.

Note: Replacing instead of repairing is referring to residential use electric pressure washers in the $80 to $300 range. One’s in the $700+ range will usually be repairable.

Okay, so not much is required for the motor. And the pump is sealed at the factory… So what does that leave?

Nozzle, hose and spray gun care

A clogged or partially clogged nozzle is not good. It prevents flow and can create upstream pressure build up.

Use an unfolded paper clip or nozzle tip cleaner to dislodge debris. Move the wire back and forth a few times to ensure the oriface is clean.

As for the hose and spray gun be sure to inspect them each use. Look for leaks and cracks/abrasions that may get worse and cause failure.

Pump care for long term and winter storage

Just like a gas powered machine’s pump requires pump care for long term and winter storage, so does an electric.

Using a pump saver product will protect the pistons and seals from damage.

See pressure washer storage section above for instructions.

Additional Maintenance Suggestions

Here’s some gear to help make maintenance easier:

Get an Hour Meter

Get an hour meter to track your power washer’s running time with ease.

Why?

- They are affordable and the one we are recommending is less than $20.

- It makes knowing when to perform a maintenance task exact and easy.

- No more setting a stop watch and writing it down in the User Manual each time you use it.

So if you want to make your life easier – check out the Searon hour meter at the link below.

See best hour meter on Amazon here…

Get Pump Saver

Pump saver is a unique anti-freeze and lubricant to protect your pressure washer pump from damage while in long term storage and over winter.

You attach it to the inlet of the pump and push the button to fill the pump with the lubricant.

It coats the pistons and seals and prevents damage from leftover mineral deposits.

It’s a must own for proper power washer care.

Get Fuel Stabilizer

Fuel stabilzer protects your engine when storing long term or over winter.

You pour a small amount in your gas tank (~15 ml or so) and it protects for the winter or a few months until next use.

There are many different brands and sizes of fuel stabilizer to buy. The one pictured is a small single use packet and is from Briggs & Stratton.

The one linked below is from STA-BIL and comes as 4 ounces.

Use the Best Fittings

Once you’ve used your pressure washer a few hours you’ll realize you want 2-3 things in a fitting:

- Quick connect (in picture is brass quick connect fitting: male/bottom and female/top)

- Brass

- Swivel fitting at the gun

Having better fittings than come out-of-the-box isn’t 100% related to maintenance but it will ease frustration.

The quick connect fittings will allow easy and quick separation of hose from pump and gun for storage and allow you to hear when it is engaged (instead of having to twist the fitting tight).

The brass material fittings (if not come stock on your machine) will be worth the upgrade over plastic because they are stronger and will last longer without leaking.

The swivel at the gun will prevent the hose from kinking and make pressure washing more fun (hose kinks are frustrating).

Check out our in-depth fittings guide here…

Apply Silicone Lubricant Grease to Rubber O-rings

Applying a silicone lubricant grease to the rubber o-rings on the hose, pump and gun connections will protect the rubber from corrosion and thus stop cracking and leaking.

It is the best type for a power washer’s o-rings because it is water resistant and non conductive.

Buy a jar at the link below.

See best silicone lube for o-rings here…

Frequently Asked Questions

I don’t own any tools – can I perform the maintenance servicing myself?

Yes. All the maintenance can be performed with just your hands and what comes with the pressure washer. You may require a wrench to take a look at the air filter and spark plug.

Is maintenance really worth my time and effort – how much will regular maintenance extend the life of my pressure washer?

Regular service is important to keeping your machine running smooth. If you never change the oil, if you never check the air filter, if you never look for leaks then eventually you will come to use it and it won’t start. It’s impossible to say the exact amount of time regular maintenance will extend the life but just your car (and it’s servicing) it’s such an easy task to guarantee a longer life.

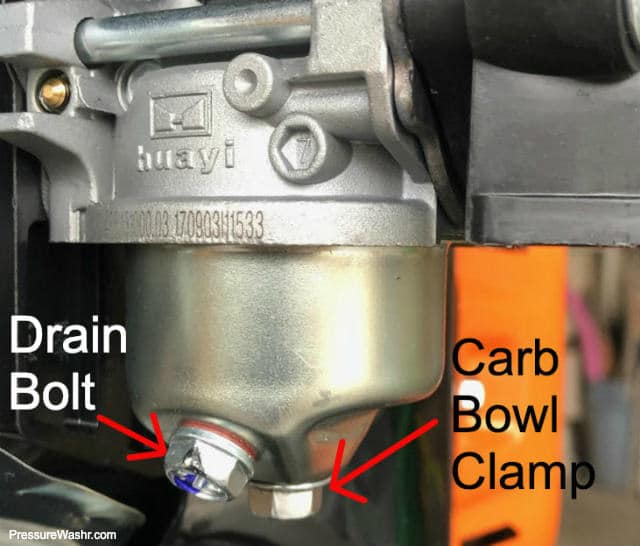

I keep hearing the word carb and carburetor in online videos (but not in this guide) – so does the carburetor require a service or tune-up or not?

No. The only thing to do with the carburetor is to drain the carb of fuel for troubleshooting or storage purposes. To do so you unscrew the drain bolt and let the fuel run out into a container.

My darn pressure washer isn’t working properly – can you help me troubleshoot?

Sure, we did an entire guide on troubleshooting here. It has everything you need to know.

How long should my pressure washer last?

The life expectancy of your pressure cleaner depends on its type, how often you use it and how well you take care of it. The first major thing to fail will almost always be the pump. So below let’s look at how long the most common pumps last.

Here’s the general rule of thumb (and assuming proper maintenance and storage):

- Residential electric – Around 300 hours use (2 hours per week for 3 years).

- Residential gas – Around 700 hours use (3 hours per week for 5 years)

- Commercial/industrial electric – 5000+ hours and easily repairable (20 hours per week for 5 years before rebuild)

- Commercial/industrial gas – 5000+ hours and easily repairable (20 hours per week for 5 years before rebuild)

You can see the major difference between residential and commercial. It is because the residential uses a wobble or axial pump and the commercial uses a triplex plunger crank driven pump. The extra lifespan comes with a hefty price increase – around $1000 for an entry level commercial machine.

Is it OK to run my pressure washer without water?

No. Running the pump dry will damage it. How? Because without the water circulating through – acting as a coolant – the pump parts get hot and start to damage the o-rings and seals in the pistons. Running dry will cause imminent damage. Do not try.

Sources

- David Kovach, Implementing a Standby Generator Maintenance Program for Diesel Engines , www.ECMweb.com, October 16, 2013.

- Tip of the Day: Drain the carburetor bowl on your lawn mower to protect the engine, Consumer Reports, October 7, 2009.

- AndrewT, Routine Motocross Bike Maintenance Tips – 4 Stroke, MotoSport.com, February 25, 2014.

![[Solution] My Pressure Washer Loses Pressure When the Trigger is Pulled](https://pressurewashr.com/wp-content/uploads/2021/06/Losing-Pressure-Thumb-768x453.png)