Guide to Pressure Washer Pumps

If you want to know the difference between the 3 best pressure washer pump types you’re in the right place.

The following information is compiled here for each pressure washer pump:

- An animation showing how each pump type functions.

- The advantages and disadvantages.

- The different brands.

- Which pressure washers use which pumps.

Pressure washing requires a pump capable of producing high pressure with low flow compared to other common pumping applications (sump pumps require high flow at low pressure). The pump also needs to be light, compact and economical.

Pressure Washing Pump Types

The are two general groups of positive displacement pumps:

- Reciprocating – Uses pistons, plungers or diaphragms.

- Rotary – Uses screws, gears, vanes or lobes.

All pressure washer pumps are in the reciprocating group and use pistons or plungers to add energy to the water. There are two main differences between the piston and plunger pump.

- The piston pump has the cylinder seal attached to the piston so it moves with it on each stroke. The plunger pump has the cylinder seal at a stationary point that the piston moves through with each stroke.

- The piston pump is driven by a drive shaft attached to the swash plate or wobble plate. The plunger pump is driven by a crankshaft.

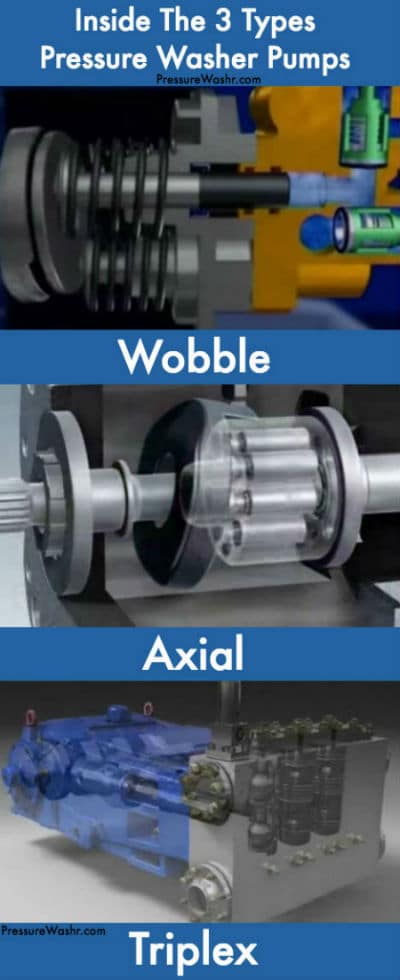

Pressure washer literature refers to 3 types of pumps (all are piston or plunger type):

- Wobble (1) and axial cam (2) pumps are directly driven by the drive shaft and use pistons

- Triplex plunger (3) pumps are camshaft/crank driven and use plungers

Take a look inside each to get a better understanding of the differences:

Also Read: 7 Little Known Facts (You Should Know) About Changing Pressure Washer Water Pump Oil

Let’s explain the pros and cons of each type and take a deeper look how each works:

Drive Shaft Driven Piston Pump

Wobble Plate Pump

Entry level pump that uses a wobble plate connected to the drive shaft to push pistons back and forth creating suction and then pushing the water out.

There is a large spring for each piston to allow the wobble plate to push against them. This causes the pump to be only 70% efficient because it has to push against the water and the springs. Wobble pumps are not economically repaired as they have many intricate parts in tough to get to places and are sealed shut before leaving the factory.

Their life span is somewhat comparable to axial cam pumps at around 200 – 400 hours (~3 hours/week for 2-3 years).

- Used in: Some pressure washers below 2500 PSI and low flow rate (less than 2 GPM).

- Pros: No seals moving back and forth with piston, self-priming, can run dry, can produce high pressures.

- Cons: Many moving parts adds complexity, low flow. Can not replace economically. Not as efficient as other pumps.

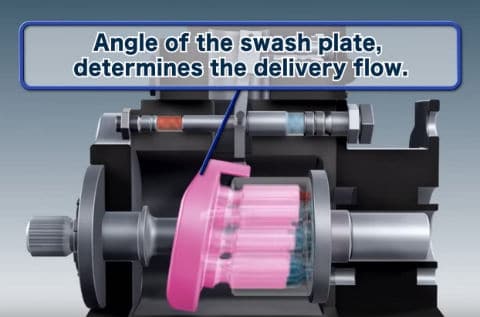

Swash Plate Pump (Axial Cam)

Intermediate level pump that offers many advantages over the wobble and is capable of higher PSI and GPM. You can see in the animation below it is similar to the wobble but slightly different in that the pistons actually rotate around the swash plate. The swash plate angle causes the pistons to stroke as they go from one side to suck up the water and then the other to push out the water. The operation allows for a larger oil reservoir and larger bearings, extending life. It rotates in the same axis as the drive shaft as it is directly connected.

Their life span is somewhat comparable but slightly better to wobble pumps at around 500 – 800 hours (~2-3x lifespan of wobble).

- Used in: Most pressure washers with less than 3500 PSI.

- Pros: Small, light and compact. Can adjust the flow by adjusting the swash plate angle. Self priming. Longer life and more efficient than wobble.

- Cons: Runs at engine speed (read: high speed) and can’t be as easily cooled as triplex pump since the cylinders are rotating. The cylinder seal is on the piston head and moves with each stroke causing it to wear. Rotating mass can cause excess vibration if not properly balanced.

Fixed vs Variable Displacement – You can adjust the angle of the swash plate in the variable displacement piston pump to vary the flow. The fixed version you can not.

Now we will look at the plunger pump which is crankshaft drive.

Crankshaft Driven Plunger Pump

Triplex Plunger Pump

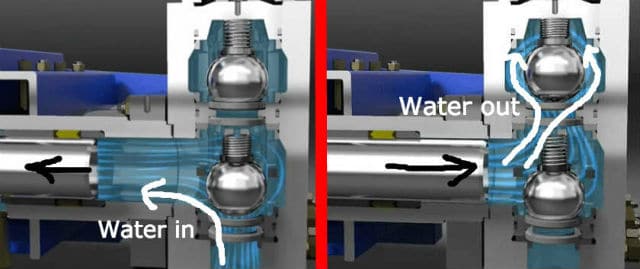

Professional level pumps use triplex pumps because it allows very high pressure and can run for thousands of hours before any maintenance. You can see in the animation below it uses a similar setup to your car engine (crankshaft, connecting rods) to drive positive action pistons to suck in water and then push out water with each stroke. They are nearly 90% efficient and run cooler as they run at less rpm than the engine. In a triplex (3 pistons) plunger pump the pistons stroke 120 degrees apart to offer smooth flow over the entire revolution of the crankshaft.

Their life span is basically limited only by how well you maintain them. The easy to access pump head and easy to replace valves make repair and maintenance economical. (~10x lifespan of axial).

- Used in: Most pressure washers above 3000 PSI.

- Pros: Very efficient. Stationary seal means increased life, less prone to leaks and much higher pressures. Lower operating speed allows it to run cool and this again increases operating life.

- Cons: Higher acquisition cost.

And a close up of how the water flows:

Now lets look at the different brands of pressure washer pumps.

Pressure Washer Pump Brands

This list is not exhaustive. Companies don’t seem to like putting what brand pump they use in their pressure washers. They prefer to just say, “axial cam” or “triplex plunger” in their literature. Let me know if something should be added.

Annovi Reverberi (AR)

AR is an Italian pump manufacturer. They also make electric motors under the Ravel brand name. They make pressure washer under the AR Blue Clean name and also sell their pressure washers under the Black & Decker and Michelin names.

Used by these brand pressure washers: AR, BE, Briggs & Stratton pressure washer pump, Campbell Hausfeld, Craftsman pressure washer pump, Generac pressure washer pump, Kranzle, Mi-T-M, Pressure-Pro.

Pump types made by AR: Wobble, Axial Cam, Triplex Plunger.

CAT Pumps

“The pump with nine lives” first introduced a 4 GPM 700 PSI pressure washer pump in 1968. Then they moved into the carwash industry in U.S. and across Europe. Today they offer hundreds of different pump models across the range of pump types.

Used by these brand pressure washers: BE, Campbell Hausfeld, DeWalt, Pressure-Pro, Simpson.

Pump types made by CAT: All types.

Comet

Comet is the U.S. distributor of another Italian pump manufacturer, Comet SpA. Their pumps are used across many industries from breweries, cement plants and oil fields to pulp and paper and pressure washers.

Used by these brand pressure washers: Excell pressure washer pump.

Pump types made by Comet: Axial, Triplex.

General Pump

Based in Minnesota, General Pump is well-known in the pressure washing and vehicle wash industry for their superior triplex plunger pumps. They offer hundreds of different models.

Used by these brand pressure washers: BE, DeWalt, Easy-Kleen.

Pump types made by General: Triplex.

Karcher

Karcher is a german company that is the biggest pressure washer manufacturer in the world. So it makes sense that they make their own pumps. They’ve designed their pumps from the ground up using corrosion-free “N-COR” material which is a combination of polyamide and glass fiber.

Used by these brand pressure washers: Karcher.

Pump types made by Karcher: Axial Cam, Triplex Plunger.

Kranzle

Kranzle is a German company that makes pressure washers, dust extractors, industrial vacuums and sweepers.

Used by these brand pressure washers: Kranzle.

Pump types made by Kranzle: Wobble, Axial Cam.

AAA Pumps (FNA Group)

AAA Pumps is a pump made by FNA Group for use in their pressure washer. They own the brand Simpson Cleaning.

Used by these brand pressure washers: Simpson.

Pump types made by AAA: Axial Cam, Triplex.

How To Buy Replacement Pump and Parts

There are many good places to buy a replacement pump. Online retailers like Amazon and RepairClinic have the most variety.

Things to be mindful of. The description of the pump will often tell all you need to know about if the pump can work with your pressure washer. However, be sure that the drive shaft measurements match… And that the engine/motor has enough power for the pump. Also be sure it is the correct configuration – vertical or horizontal – for mounting.

Amazon.com Pumps – There are hundreds of pumps to choose from. Find yours at this link and use the refine search filter on the left sidebar to narrow down the search.

Pump Repair

Contact your local pressure washer dealer for pump repair services.

Learn how to change your pressure washer water pump oil here.

Sources

- “Positive Displacement Pumps” by Joe Evans, Ph.D. Pumped101.com. Retrieved 12 August 2015.

- Michael Volk (21 October 2013), Pump Characteristic and Applications, Third Edition, Page 34. Retrieved 12 August 2015.

- “How Plunger Pump Works – Animation“. TechTrixInfo youtube.com channel. Viewed 12 August 2015

- “Animation – How an axial flow variable displacement piston pump works.” TechTrixInfo youtube.com channel. Viewed 12 August 2015.

- “Fixed Displacement Piston Pump“. mekanizmaler youtube.com channel. Viewed 11 August 2015.

- “Pump Types Guide – Find the right pump for the job“. Pumpscout.com. Retrieved 13 August 2015.

- “Pressure Cleaner Pump, Nozzles & Detergent“. www.QualityPumps.com. Retrieved 13 August 2015.